BIO PURGE® TECHNOLOGY

Advanced Microwave

Disinfection for Medical Waste

BIO PURGE® TECHNOLOGY

Bio Purge® is an advanced medical waste treatment system exclusively provided by Cleavion Corp, utilizing microwave disinfection technology to safely, efficiently, and sustainably neutralize infectious medical waste—without incineration or harmful chemicals.

Technology Overview

What Is Microwave Disinfection Technology?

Microwave disinfection technology uses electromagnetic waves with wavelengths ranging from 1 to 1000 millimeters and frequencies between several hundred megahertz and 3000 MHz. For medical waste disinfection, Bio Purge® operates at internationally recognized frequencies of:

2450 ± 50 MHz

- 915 ± 25 MHz

These frequencies are proven to deliver consistent and effective disinfection performance.

When microwaves pass through a medium, they may either be absorbed or transmitted. Microwave-absorbing media, such as water, absorb microwave energy efficiently and convert it into heat. Since most medical waste contains moisture, water molecules rapidly absorb microwave energy and vibrate billions of times per second. This molecular friction generates high temperatures, enabling rapid and thorough disinfection.

In contrast, materials that do not absorb microwaves act as conductors, allowing energy to pass through with minimal thermal effect—ensuring targeted and efficient heating only where needed.

Beyond thermal effects, microwave energy also impacts microorganisms through:

Electromagnetic field interactions

Disruption of microbial metabolism

Structural damage to microbial cells

Together, these mechanisms ensure high-level pathogen destruction and reliable sterilization.

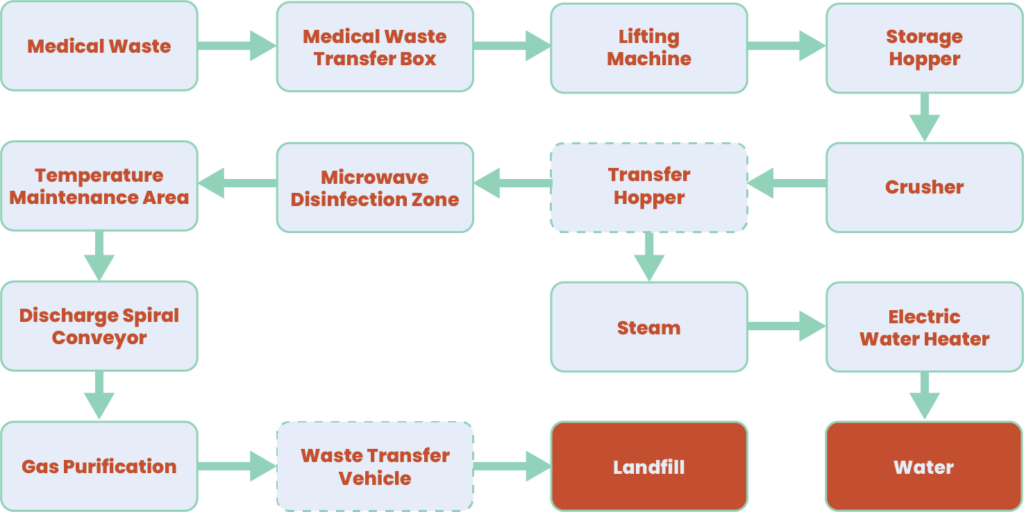

Process Flow Overview

Fully Automated Medical Waste Disinfection System

Medical Waste Microwave Disinfection Process Flow

Medical Transfer Box – Waste is securely contained at the source

Lifting Machine – Hydraulic lifting system raises waste containers

Transfer Hopper – Automatic opening and feeding of waste

Crusher – Waste is shredded for uniform treatment

Microwave Disinfection Zone – Microwave radiation with steam-assisted heating

Temperature Maintenance Area – Ensures consistent disinfection conditions

Gas Purification System – Exhaust gases treated and purified

Discharge Conveyor – Ozone deodorization spiral conveyor

Waste Storage Bin – Treated waste transferred for final disposal

System Components

Bio Purge® Equipment Configuration

The microwave disinfection system consists of the following integrated units:

Feeding Unit

Hydraulic lifting mechanism for sealed waste containersCrushing Unit

High-efficiency crusher for size reduction and uniform exposureMicrowave Disinfection Processing Unit

Microwave generator delivering controlled disinfection energyDischarge Unit

Spiral discharger for treated waste removalAutomatic Control Unit

Centralized control system for safe and efficient operationExhaust Gas Treatment Unit

Gas scrubber combined with high-efficiency filtration and UV light- Wastewater Treatment Unit

No wastewater generation during operation

Featured Machine: Bio-Purge JRX-5T

Bio-Purge

Technical Features & Advantages

Featured Machine: Bio-Purge JRX-8T

Clean and Environmentally Responsible

Microwave disinfection offers:

Rapid processing

Strong penetration

Uniform internal and external heating

The process produces no toxic or harmful substances, resulting in zero secondary environmental pollution. The primary operational media—high-temperature steam and electromagnetic waves—make Bio Purge® a truly clean technology.

High Sterilization Effectiveness

(Log6 Standard)

By adjusting time and temperature parameters:

Sterilization of reproductive bacteria and fungi achieves Log6 standard

Kill rate for Bacillus subtilis spores (ATCC 9372) reaches Log4 standard

The combination of microwave energy and steam ensures deep penetration into microorganisms, securing consistent disinfection results.

Cellular-Level Microbial Destruction

Within the microwave field, microbial cell structures are disrupted, upsetting the internal and external balance of cellular materials and leading to irreversible cell death.

Why Bio-Purge Stands Out

Bio-Purge is an advanced, fully integrated living (biological) medical waste disposal system that combines high-performance machinery, intelligent software, and operator workstations to deliver safe, compliant, and environmentally responsible waste treatment for healthcare facilities.

All-in-One Integrated System

Unlike conventional waste disposal solutions, Bio-Purge combines hardware + software + operator workstations into one unified platform.

Smart Software Control

Built-in intelligent software enables real-time monitoring, tracking, reporting, and compliance documentation.

Multiple Models for Different Facility Sizes

Scalable systems designed for clinics, laboratories, hospitals, and large medical centers.

Regulatory & Environmental Compliance

Designed to meet local and international healthcare waste management standards.

Reduced Human Contact & Infection Risk

Automated processing minimizes direct handling of hazardous biological waste.

Eco-Conscious Technology

Optimized processing reduces environmental impact while ensuring safe neutralization.

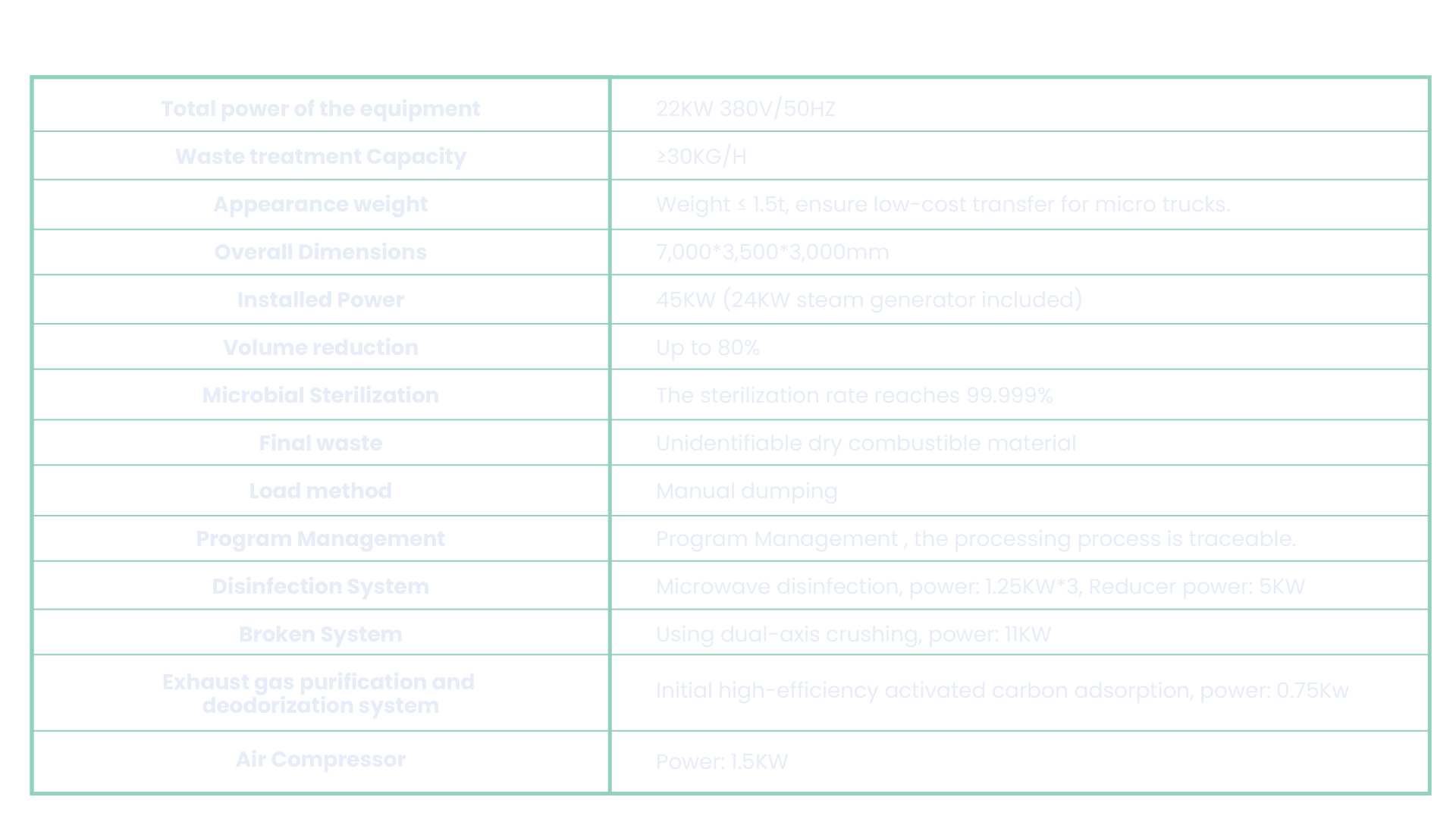

Technical Specification

Bio-Purge VS OTHER MACHINES

Bio-Purge

- Uses microwave disinfection + dual-shaft crushing

- Sterilization rate: 99.999%

- Ensures uniform, deep sterilization

- Enclosed stainless-steel chamber prevents contamination

- Low-power microwave technology

- Exhaust gas purification system

- No toxic emissions, no secondary pollution

- Eliminates secondary transport risks

- Designed for on-site hospital disposal

- Prevents infection spread during transport

- Suitable for all hospital levels

- Integrated crushing + disinfection

- Waste volume reduced by up to 80%

- Dual-shaft servo motors ensure thorough shredding

- Compact design

- Requires only ~20 square meters

- High system integration

- Automated electrical control system

- Medical waste weighing system

- Data acquisition and traceability system

- Full process monitoring and compliance-ready

Other waste Disposal Machine

- Steam autoclave: effective but uneven heat penetration

- Chemical disinfection: chemical residue risk

- Incineration: high temperature but air pollution concerns

- Incineration produces dioxins, ash, and harmful gases

- Off-site disposal increases infection spread risk

- Chemical methods may cause environmental contamination

- Often require centralized off-site facilities

- Increased logistics cost and biohazard risk

- Autoclaves reduce pathogens but not volume

- Incinerators reduce volume but at high energy cost

- Incinerators and centralized systems require large facilities

- High infrastructure and installation cost

- Manual operation common

- Limited or no traceability

- Higher risk of human error

Featured Machine: Bio-Purge JRX-0.5T

Featured Machine: Bio-Purge JRX-1T